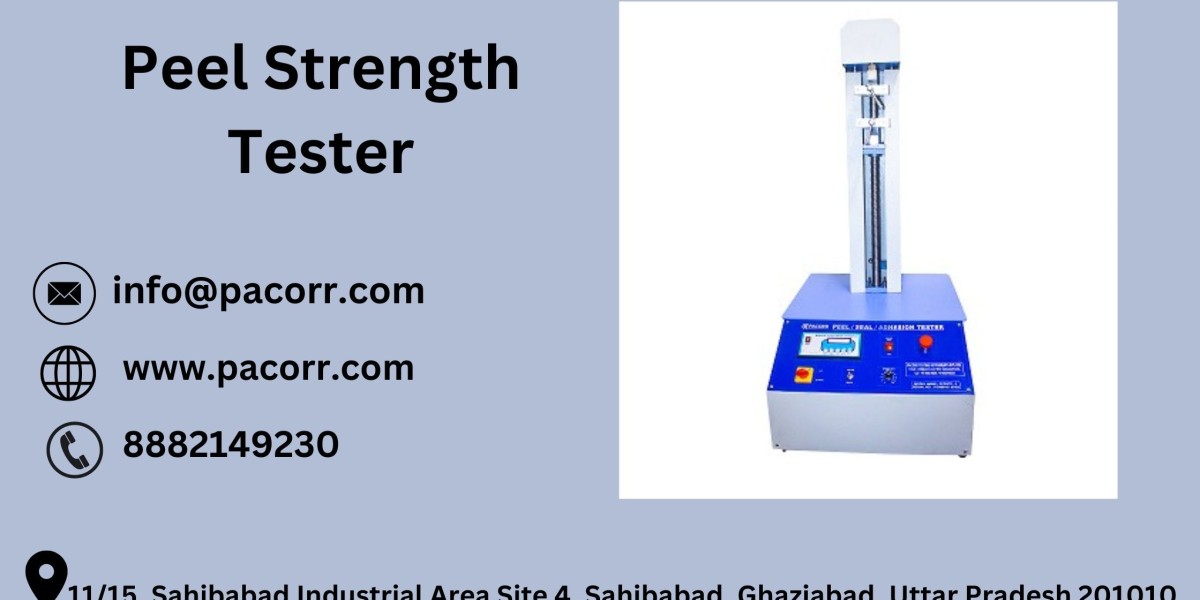

Understanding the Peel Strength Tester: A Crucial Tool for Adhesive Quality Assessment

In today's manufacturing world, the importance of quality control cannot be overstated. Companies across industries strive to ensure that their products not only meet but exceed customer expectations. For industries relying on adhesives, laminates, and coatings, the Peel Strength Tester becomes an indispensable tool in their quality assurance arsenal. This article will delve into the significance of this testing equipment, its applications, and why it is a critical component for industries worldwide.

What is a Peel Strength Tester?

A Peel Strength Tester Price is a specialized instrument used to measure the force required to peel a material from its substrate. This test is essential in determining the bond strength of adhesives, laminates, coatings, and other materials that rely on surface adhesion. The test helps manufacturers assess the durability, reliability, and overall quality of their products, ensuring they meet the necessary standards for both functionality and safety.

How Does the Peel Strength Tester Work?

The Peel Strength Testing operates by applying a controlled force to the material being tested. The material is placed in the machine, and a peel force is applied at a specific angle, usually 90 or 180 degrees. As the test proceeds, the machine records the force required to separate the material from its substrate. The results are then analyzed to determine the peel strength, which is crucial for evaluating the adhesive quality of the product.

Applications of Peel Strength Testing

Peel strength testing Price is widely used across various industries, including packaging, automotive, electronics, and textiles. Some of the key applications include:

- Packaging Industry: Ensuring that labels, seals, and tapes adhere properly to packaging materials to prevent tampering and ensure product safety.

- Automotive Industry: Testing the strength of adhesives used in vehicle components to ensure they can withstand environmental stresses and maintain their integrity over time.

- Electronics Industry: Evaluating the adhesion of protective coatings on electronic devices to ensure they provide adequate protection against moisture, dust, and other contaminants.

- Textile Industry: Assessing the bonding strength of laminates and coatings applied to fabrics to ensure they can withstand washing, stretching, and wear without delaminating.

Why is Peel Strength Testing Important?

The importance of Peel Strength Tester Manufacturer lies in its ability to predict the performance and durability of adhesive bonds in real-world conditions. By conducting peel tests, manufacturers can:

- Ensure Product Reliability: Products that rely on adhesives must maintain their integrity under various conditions. Peel strength testing helps verify that the adhesive will hold up over time, even under stress.

- Meet Industry Standards: Different industries have specific standards for adhesive strength. Peel testing ensures that products meet or exceed these standards, providing confidence in their quality and safety.

- Reduce Material Waste: By identifying weak adhesive bonds early in the production process, manufacturers can prevent defective products from reaching the market, thereby reducing material waste and associated costs.

- Enhance Customer Satisfaction: Products that fail due to poor adhesive strength can lead to customer dissatisfaction and damage to the brand's reputation. Peel strength testing helps ensure that products perform as expected, leading to higher customer satisfaction.

Features of Pacorr’s Peel Strength Tester

Pacorr’s Peel Strength Tester is designed with advanced features to provide precise and reliable results. Key features include:

- High-Precision Load Cell: Ensures accurate measurement of peel force, providing reliable data for quality control.

- User-Friendly Interface: Simple to operate, allowing operators to quickly set up tests and obtain results without extensive training.

- Customizable Test Parameters: Offers flexibility in test settings, including peel angle and speed, to accommodate different materials and industry standards.

- Durable Construction: Built to withstand rigorous testing environments, ensuring long-term durability and reliability.

Conclusion

The Peel Strength Tester Price is an essential tool for industries that rely on adhesives and coatings. By providing accurate measurements of bond strength, this equipment helps manufacturers ensure the quality and durability of their products. Whether in packaging, automotive, electronics, or textiles, peel strength testing plays a vital role in maintaining high standards of product performance and safety. Pacorr's Peel Strength Tester Supplier offers a reliable and efficient solution for companies looking to enhance their quality control processes and deliver superior products to their customers.